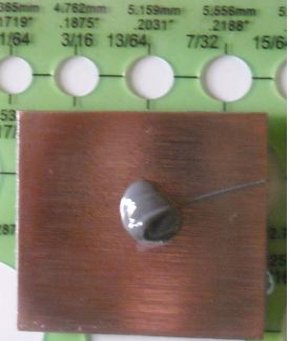

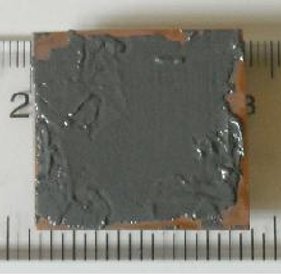

Example of Correct Application

Proper application of an approximately 5.0-5.5 mm bead on the center of the IHS; the example on left utilizes a synthetic IHS. The primary reason a compression type spreading is recommended is that the best results are attained with this method.

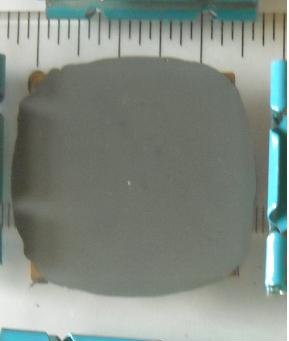

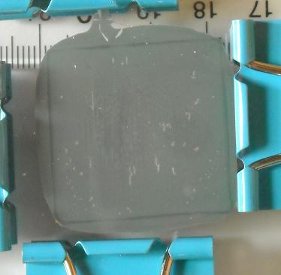

Here is a simulated IHS clamped between two slides with 50 psi force applied; the 5.0mm-5.5mm bead application spread pattern created by the recommended compression technique. Note paste is smooth and even with no visible air pockets.

Note on Application amount

Incorrect Line Application with Lapacian Growth

Acceptable Line Application

A 3/4 compound line is acceptable on a rectangular piece as long as width of the die does not exceed 1.5cm. More than that will likely initiate Lapalcian Growth and entrain air into the thermal joint.

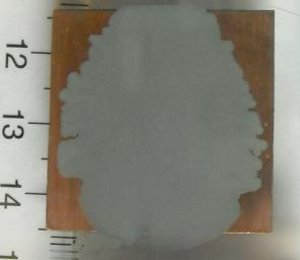

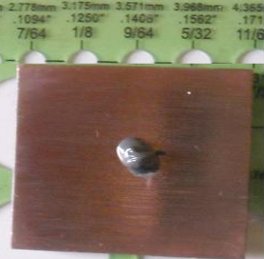

Incorrect Manual Spread Application

The manual Spreading of a compound is highly discouraged; the manipulation, folding of the compound, as well as surface irregularities will add air into the final assembly.

This assembly shows bubbles of air that, under thermal load, will expand and migrate together creating voids that affect thermal performance and reliability The manual Spreading of a compound is highly discouraged; the manipulation, folding of the compound, as well as surface irregularities will add air into the final assembly.

Final Reminder - Use the Correct Amount

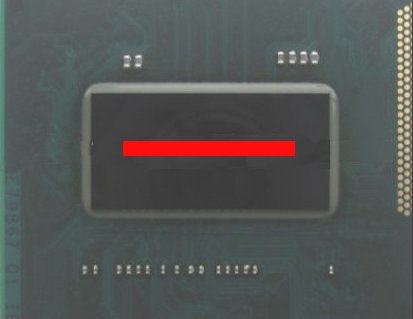

Under Application with a 3mm Bead on a 30mmX30mm Die is not enough.

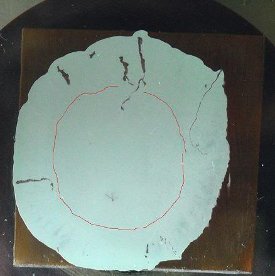

Resulting assembly is an example of Laplacian Growth; note the entrained air in the radial halo.

Laplacian Growth shown here with a low viscosity competition compound and applied with a compression spread with a glass slide. This demonstrates that while visually the area seems to be covered the entrainment of air is obvious and certainly inadequate to fill any void space.